Researchers create 3D printed food for people with swallowing difficulties

Researchers have developed meals suitable for people with dysphagia (swallowing difficulties) using 3D printing technology.

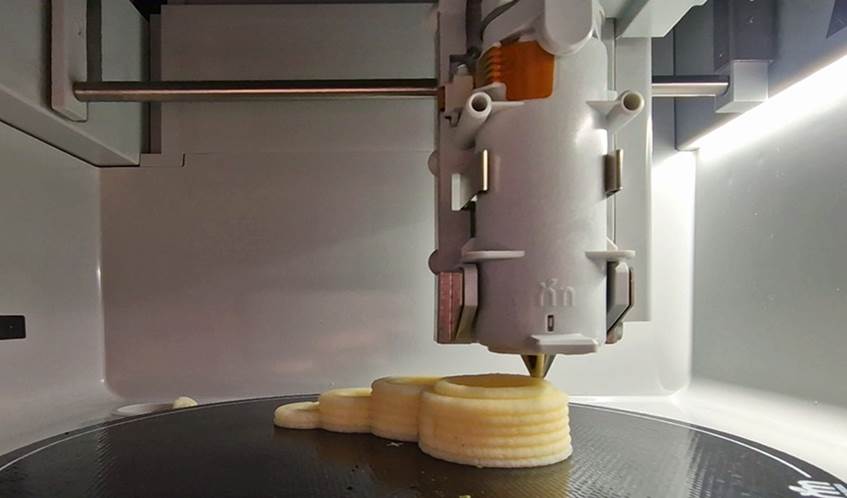

An international team of academics led by UWE Bristol has become the first to use an extrusion-based 3D food printer to produce multi-ingredient, nutritionally balanced and visually appealing meals which are safe to swallow and digest.

Estimates suggest that up to 16 per cent of the UK population has dysphagia, with the condition more common among older adults and individuals with certain health conditions including stroke patients and dementia patients.

People with the condition often need to modify their diet to make swallowing easier and safer by eating pureed foods, thickened liquids or soft foods. However, pureed foods can be bland and unappetising in taste and texture, and lacking in nutritional variety and density.

Meals produced for the research, led by Dr Alexandros Stratakos, were developed alongside clinical nutritionists to ensure they were complete, multi-ingredient, nutrient-rich dishes suitable for people with dysphagia. They were made using pureed garden peas, strained Greek yogurt, extra virgin olive oil, powdered organic mint leaves and vegetable stock.

Researchers experimented by trying different novel combinations of food grade thickeners and gelling agents until they identified an optimum formulation that provided a texture and viscosity suitable for people with dysphagia.

Dr Stratakos, Associate Professor in Sustainable Agri-Food Production at UWE Bristol, said: “With our 3D printed food, there is significantly less risk of food particles sticking in the throat or the oesophagus, which can be very problematic for people with dysphagia. It requires less chewing and has a specially formulated structure which gives more control of the food to the person with dysphagia.

“Previous research on 3D printed food suitable for dysphasia has focused on meals with only one or a small number of ingredients and has paid less attention to the nutritional profile of the food. Our food product is the first that is suitable for people with dysphagia, but at the same time is nutritious, palatable and rich in calories.

“As researchers we try to solve real life problems and dysphagia is a very important one. It is a growing issue due to our aging population and will become a bigger healthcare burden both in the UK and internationally. This study highlights the importance of bringing together multidisciplinary expertise, in this case on food science, additive manufacturing and dietetics/nutrition, to develop novel solutions for real-world problems.”

"As researchers we try to solve real life problems and dysphagia is a very important one. It is a growing issue due to our aging population and will become a bigger healthcare burden both in the UK and internationally."

Dr Alexandros Stratakos

To make the food, the researchers added ingredients to cartridges which are placed inside the 3D printer. When the machine is switched on, the ingredients are extruded as ‘ink’ through nozzles onto a plate. Layers of ‘ink’ are deposited on the surface of the plate in a pre-programmed shape, then multiple layers are added to build a three dimensional object. Meals can be produced quickly (approximately 20 minutes) and printed in a variety of attractive patterns and shapes.

A survey showed UK-based dysphagia patients, and their carers, were ‘overwhelmingly positive’ about the concept of the type of 3D-printed meals produced in the study. Respondents said they would be willing to purchase the meals, which are high in fibre and protein, if they were commercially available.

Dr Stratakos, an academic in UWE Bristol’s School of Applied Sciences, said: “It is common for people to be hesitant about trying new products or new technologies but the survey we conducted showed that people would be willing to try our printed food. The respondents also indicated that they would be even more willing if they knew more about the technology being used.

“We’re very pleased with the project, and the results we achieved, and we are now in the process of trying to build new collaborations and apply for further grants to secure funding to expand the project further.”

Following the success of their laboratory-based research, the academic team now hope to secure funding to conduct a clinical trial. Dr Stratakos said he could envisage 3D food printers eventually being introduced to care homes and hospitals to enable food to be produced on site and served to patients.

He said: “It's important to evaluate the suitability of this product, and this would involve a clinical trial where it would be tested by patients with dysphagia. We have taste tested the food ourselves here in the lab and it tastes great.”

Dr Clare Jonas, Research Communications Lead at the Stroke Association, said: “Swallowing problems affect around half of all stroke survivors. It can be dangerous, causing foods to ‘go down the wrong way,’ which can lead to choking or lung infections. Safety is therefore a primary concern but offering healthy and palatable meals matters too.

“We are pleased to see research being conducted in this area, because we know that finding ways to reduce the risk of lung infections and other complications after stroke is important to stroke survivors, as is understanding how to support them in regaining the abilities needed for everyday life.

“This research shows promising developments of treatment options to help stroke survivors reach their specific goals, and we look forward to seeing further results.

“The Stroke Association is also funding research into this area, currently running a feasibility study to test alternatives to thickened liquids for stroke survivors with dysphagia.”

The project was an international collaboration between the UK, Greece and Serbia, including four researchers from UWE Bristol and academics from the University of the Peloponnese and University of Novi Sad. The full research paper was published in the Food Hydrocolloids academic journal.

Related news

12 December 2025

UWE Bristol’s environmentally conscious and student-focused accommodation wins three awards

Purdown View, the world's largest certified Passivhaus student accommodation development, has been recognised at Property Week Student Accommodation Awards.

13 November 2025

Alliance Medical and UWE Bristol launch UK’s first PET-CT postgraduate certificate

In a move set to transform imaging education, Alliance Medical (AML) and UWE Bristol have joined forces to co-design and develop the UK’s first PET-CT Postgraduate Certificate (PG Cert).

10 November 2025

Lessons from Low Traffic Neighbourhoods will drive better public engagement, study finds

Lessons from Low Traffic Neighbourhoods have informed a new toolkit to improve engagement with the public on challenging local street issues.

29 September 2025

Smartphone use hitting struggling pupils hardest, major study finds

Young people struggling with their studies at school are much more likely to have negative experiences on their smartphones than their better performing peers, a major new study has found.

11 September 2025

New study to investigate augmented reality as an intervention for emotionally based school avoidance

A UWE Bristol researcher will support a new study exploring whether an augmented reality board game can help young people with emotionally based school avoidance (EBSA).

28 July 2025

Student wins bronze medal at World Aquatics Championships on her graduation day

UWE Bristol sports rehabilitation student Izzy Thorpe made waves at the World Aquatics Championships winning a bronze medal in artistic swimming on the same day she was meant to be crossing the stage at her university graduation ceremony.

28 May 2025

Leading organisations fighting to end youth violence in cities join UWE Bristol event panel

Leaders from Bristol-based Empire Fighting Chance and Canadian non-profit REACH will speak at the next Bristol Distinguished Address Series.

09 May 2025

UWE Bristol among first universities in UK to introduce sanitary waste bins in male toilets

UWE Bristol is among the first universities in the UK to introduce sanitary waste bins in male toilets for the disposal of incontinence products.

11 April 2025

UWE Bristol academics among emerging scientific leaders to receive share of £7.6m for health research

Two UWE Bristol researchers are among the recipients of a £7.6 million investment from the Academy of Medical Sciences aimed at tackling urgent health challenges.

09 April 2025

New research to support a thriving health and care workforce is launched

A national research partnership will explore ways to support wellbeing and sustainability in the NHS and social care same day and urgent care workforce.

10 March 2025

UWE Bristol to explore the power of open water swimming at upcoming event with The Wave founder Nick Hounsfield

An inspiring tale of grit and resilience will be told to audiences at the first BDAS event of 2025 as UWE Bristol welcomes Nick Hounsfield, founder of The Wave.

28 February 2025

Paramedics in GP surgeries may ease workload but not NHS costs, study finds

Paramedics working in GP surgeries help reduce GP workload but do not contribute to cost savings to the NHS, according to the first major study of the clinical and cost-effectiveness of paramedic compared with GP consultations.

You may also be interested in

Media enquiries

Enquiries related to news releases and press and contacts for the media team.

Find an expert

Media contacts are invited to check out the vast range of subjects where UWE Bristol can offer up expert commentary.

School of Applied Sciences

We have an excellent reputation for the quality of our teaching and approvals from external bodies such as the Forensic Science Society, the Institute of Biomedical Sciences and the Institution of Environmental Sciences.

We're creating tomorrow, today. RISE

Collaborating with industry, public sector bodies and communities, we’re redefining horizons and challenging conventions to impact lives positively.